What is Polymeric Positive Temperature Coefficient :

Polymeric Positive Temperature Coefficient is an over current electronic protection component , It use macromolecule organic polymer under high pressure, high temperature, sulfuration reaction conditions, with conductive particles material, after special processing technology. Polymeric Positive Temperature Coefficient (PPTC) is a kind of positive temperature coefficient polymer thermistor is used for overcurrent protection, which can replace current fuse.

When the circuit works well, its resistance is very small (voltage is very small ) , the PPTC temperature will increase when the circuit appear overcurrent ,the resistance increases sharply by several orders of magnitude, and reducing the current in the circuit to under the safe value. so that it take a effective to protect the circuit , and after the over current disappear, it automatically revert to low resistance.

Traditional fuses over-current protection can only be protected one time , If it burns, it needs to be replaced a new one ,The PPTC has over current , over heat protection and automatic recovery dual function. The effect is similar to the switch component , but the response speed is slow.

The classification of PPTC:

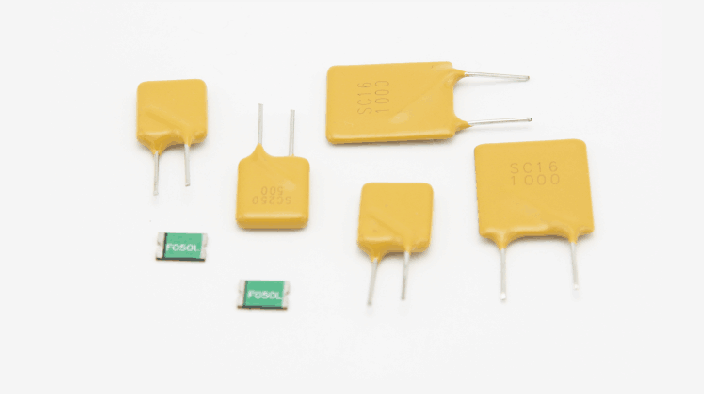

PPTC has three types of packaging : Radial lead type , thin sheet type (belt type ) and Surface mount device type (SMD) .

Package type : 0603,0805,1206,1210,1812,2016,2920

Radial lead type -- withstand voltage (V) : 06,16,30,60,90,130,250,600

What is the function of PPTC :

PPTC -- Polymeric Positive Temperature Coefficient , It consists of a polymer matrix and Carbon black particles which can make electric conduction to the PPTC . Since Polymeric Positive Temperature Coefficient is conductor, there will be electric current passing through it .When an overcurrent passes through it , The heat generated (I2R) will inflate it . As a result, carbon black particles will separate and the resistance of polymer self restoring fuse will rise. This will enable the PPTC to generate heat faster and inflate bigger , so as to further increase the resistance.When the temperature reaches 125℃, the resistance changes significantly, so that the current is obviously reduced. At this point, the small current flowing through the PPTC is sufficient to keep it at this temperature and in a high impedance state. After the failure recovery , the PPTC and Carbon black particles both recover to the original type , then reduce the resistance to the original level .The above process can be repeated many times .

The working principle of PPTC is a dynamic balance of energy. The current flowing through the PPTC element produces heat due to the relationship of PPTC, and the heat generated is all or partially emitted into the environment, and the heat of the PPTC element will be increased without the heat released from it.

The temperature at normal work is low, and the heat generated and the heat emitted are balanced. When it in a low resistance state , it is not working on the circuit .When the current flowing through the PPTC component increases or the ambient temperature rises, PPTC still does not working if The heat generated and the heat emitted are in balance . When the current or ambient temperature is raised again, the PPTC will reach a higher temperature.If the current or environmental temperature continues to increase again, the heat generated will be greater than the heat emitted, the temperature of the PPTC element increases sharply. At this stage, a very small temperature change will cause a significant increase in the resistance value, at this time the PPTC element is in the high resistance protection state.After the failure recovery , the PPTC and Carbon black particles both recover to the original type , then reduce the resistance to the original level , so that it could work again like a new PPTC component .

The Advantages and Disadvantages of Polymeric Positive Temperature Coefficient:

Advantages :

1. Have Initial resistance value.

2. It has been in a high resistance state until the fault is excluded

3. PPTC works faster because of smaller size

4. Can also provide over current protection for many times .

5. Cycle life can be regarded as infinity

Disadvantages:

Have a preference for the temperature , it have a best effection when use into 25℃ temperature condition .

The Application of Polymeric Positive Temperature Coefficient :

It can be used in computer and its external equipment, mobile phone, battery group, remote communication and network equipment, transformers, industrial control equipment, automobile and other electronic products, and play an over current or over temperature protection.

Digital products; cameras; mobile phones; electronic photo frames; control boards; toys; audio and other consumer electronics; power supply; communication equipment; security products; converters. PPTC can be found in low-voltage power supply products and lightning protection devices in the market.

The Selection of the PPTC :

Choose the right type according to the maximum working voltage ( V ), normal working current ( I ), fault current ( If )and maximum ambient temperature( TM ). When use into the maximum ambient temperature ( TM ) , it should be satisfied :

①IH (TM)a little bigger than I

②IT (TM)≤If≤Imax

③Vmax≥V

The circuit voltage and current are referred to as DC or AC effective values.

PPTC is usually connected in series to protect the circuit front-end. Replacing current fuse can remove the trouble of frequent replacement.